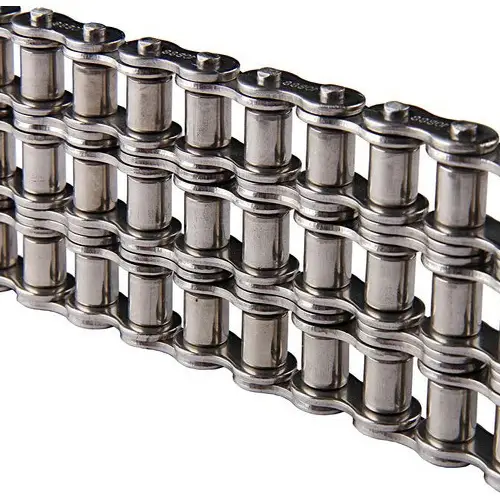

China Standard Double Roller Chain for High-Quality Transmission

Our China Standard Double Roller Chain Standard Conveyor Gear is the perfect solution for your industrial power transmission needs. Made with high-quality cast iron and stain steeling, these roller chains are designed to withstand heavy loads and provide long-lasting performance. With a large pitch and short pintle, these chains are perfect for a wide range of applications, from elevators to general industrial power transmission.

Precision Roller Chains for Various Applications

At HZPT Chain Corp., we offer a full range of both precision roller chain and engineered roller chain. Our roller chains are available in various sizes and pitch configurations to meet the needs of your specific application. In addition to our standard roller chains, we also offer chains with attachments and special materials to meet your unique requirements.

Wide Range of Chains Available

Our chains are designed for various applications, including:

- Bicycle Chain: 408, 410, 415

- Motorcycle Chain: 04C, 25H, 06C, T3, 270H, 415H, 420, 420L, 425, 428, 428H, 520, 525, 530

- ASA Roller Chain: 35, 40, 41, 50, 60, 60H, 80, 80H, 100, 120, 140, 160, 200, 240 (Catalog)

- Chain (British Standard): 05-B, 06-B, 08-B, 10-B, 12-B, 16-B, 20-B, 24-B, 28-B, 32-B, 40-B (Catalog)

- Large Pitch Chain: 100, 100H, 120, 120H, 140, 140H, 160, 160H, 180, 200, 240

- Extend-Pitch Precision Roller Chains: 208A, 208B, 210A, 210B, 212A, 212B, 216A, 216B, 220A, 220B, 224A, 224B, 228B, 232B

- Roller Chains for Beer Bottling Conveyors: CK-70S, CK-100S, CK-100SA, CK-100SC, CK-133XA, CK-140X, CK-140XA, CK-150X, CK-150S, CK-154X, CK-155X, CK-155XA, CK-160X, CK-160XA, CK-160XB, CK-160XC, CK-165X, CK-165XA, CK-169, CK-180X, CK-180XA, CK-200S, CW-102, CW-127

- Implement Roller Chains for Conveyors: 81X, 81XH, 81XHH, CA550, CA555, CA620

By adopting integrated optimum design of the structural dimensions, parts material and heat treatment process, the ultimate tensile strength of SP series high-strength roller chain is 28% more than that of A series standard roller chain. Moreover, it has excellent performances of fatigue strength and impact resistance.

Other Products for Industrial Use

In addition to our high-quality roller chains, HZPT Chain Corp. also offers a wide range of other products for industrial use. Our products include agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, steel chains, pulleys and pulleys, planetary gearboxes, timing pulleys, bushings, and more. We pride ourselves on providing high-quality products at preferential prices, along with considerate services. Customers are welcome to customize drawings and samples to meet their specific needs.

Frequently Asked Questions (FAQs)

1. What are precision roller chains?

Precision roller chains are chains that are designed with tight manufacturing tolerances and strict quality control to ensure consistent performance and durability.

2. What materials are used in HZPT roller chains?

HZPT roller chains are made with high-quality cast iron and stain steeling for superior strength and durability.

3. What applications are HZPT roller chains suitable for?

Our roller chains are suitable for a wide range of applications, including conveyor and elevator transfer, general industrial power transmission, and specialty applications with attachments and/or special materials.

4. What is the ultimate tensile strength of SP series high-strength roller chain?

The ultimate tensile strength of SP series high-strength roller chain is 28% more than that of A series standard roller chain, thanks to its integrated optimum design of the structural dimensions, parts material, and heat treatment process.

5. Does HZPT Chain Corp. offer customization services?

Yes, we welcome customers to customize their drawings and samples to meet their specific needs.

When it comes to pitch chains, there are a few key things that you need to keep in mind. First and foremost, pitch chains are an essential component of any machinery that relies on sprockets to function. These chains are designed to transmit power from the motor to the sprockets, which in turn drive the machine.

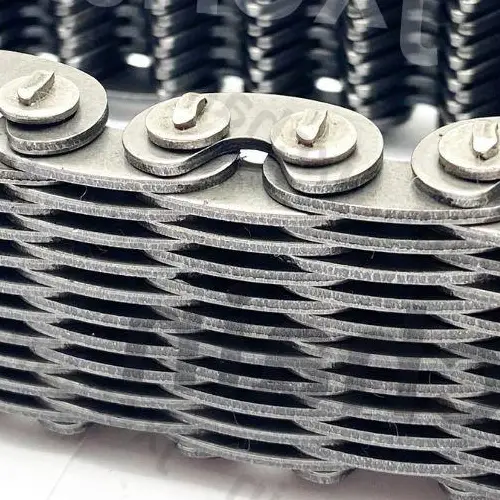

One of the most important things to consider when selecting pitch chains is the pitch itself. This refers to the distance between the rollers on the chain. It’s crucial to choose a pitch size that matches the sprockets that your machinery uses. If the pitch is too small or too large, the chain won’t fit properly and could cause serious damage to your equipment.

Another key consideration is the material that the pitch chain is made from. There are a variety of different materials to choose from, including steel, stainless steel, and plastic. The material you choose will depend on the specific needs of your machinery and the conditions it will be operating in.

At [company name], we offer a wide range of pitch chains to suit a variety of applications. Our replacement parts are designed to meet or exceed the performance of the original spare parts, ensuring that your machinery operates at peak efficiency. If you need help selecting the right pitch chain for your equipment, our team of experts is always here to help. Contact us today to learn more.

Introduction to Pitch Chain Performance Characteristics

Pitch chain, also known as roller chain, is a crucial component in various industries. Its performance characteristics make it highly reliable and efficient in transmitting power and conveying materials. Let’s take a closer look at the key performance characteristics of pitch chain:

1. High Strength: Pitch chain is designed to withstand heavy loads and high tension, ensuring reliable power transmission in demanding applications. Its sturdy construction ensures long-lasting performance even in harsh operating conditions.

2. Low Friction: The design of pitch chain minimizes friction between the chain and the sprocket, resulting in efficient power transmission and reduced energy loss. This characteristic not only enhances the overall efficiency of the system but also contributes to the longevity of both the chain and the sprocket.

3. Wear Resistance: Pitch chain is engineered to withstand wear and tear, enabling it to endure repetitive motion and maintain optimal performance over an extended period. The materials used in its construction are carefully selected to enhance durability and minimize the need for frequent replacement.

4. Noise Reduction: Pitch chain is designed to operate quietly, reducing noise levels in the machinery or equipment where it is used. This characteristic is particularly important in industries where noise reduction is essential for a comfortable and safe working environment.

Types and Characteristics of Pitch Chain

Pitch chains come in various types, each with unique characteristics that make them suitable for specific applications. Here are some commonly used types of pitch chain:

1. Standard Pitch Chain: This type of chain is widely used and is known for its versatility and compatibility with a wide range of applications. It is commonly used in conveyor systems, power transmission, and other industrial machinery.

2. Double Pitch Chain: As the name suggests, this type of chain has a longer pitch length compared to standard pitch chain. It is typically used in applications that require longer spans between shafts or when a lighter load is involved.

3. Hollow Pin Chain: This type of chain has hollow pins that allow for easy attachment of various accessories or attachments. It is commonly used in industries that require frequent customization or the addition of components to the chain.

4. Stainless Steel Chain: Made from corrosion-resistant stainless steel, this type of chain is ideal for applications in humid or corrosive environments. It offers excellent resistance to rust, chemicals, and extreme temperatures.

5. Nickel-Plated Chain: Nickel-plated pitch chain provides enhanced corrosion resistance and improved aesthetics. It is commonly used in industries where a visually appealing finish is desired or where protection against corrosion is crucial.

Application of Pitch Chain in Various Industries

The versatility of pitch chain enables its widespread use across different industries. Here are some examples of how pitch chain is applied in various fields:

1. Automotive Industry: Pitch chain is utilized in automotive engines, transmissions, and timing systems to ensure precise power transmission and reliable performance.

2. Agricultural Machinery: Pitch chain is employed in agricultural equipment such as harvesters, tractors, and conveyors, enabling efficient power transmission and smooth operation in challenging farming environments.

3. Food and Beverage Industry: Pitch chain is used in food processing and packaging machinery, ensuring hygienic and reliable conveying of food products throughout the production process.

4. Construction Machinery: Pitch chain is crucial in construction equipment like excavators, cranes, and bulldozers, providing the necessary power transmission for heavy-duty operations.

5. Industrial Manufacturing: Pitch chain finds extensive use in manufacturing equipment, such as conveyor systems, assembly lines, and robotics, facilitating efficient material handling and production processes.

The value and importance of pitch chain in these industries cannot be overstated, as it ensures smooth operation, improves productivity, and enhances overall efficiency.

Future Development Trends and Opportunities

The pitch chain industry is constantly evolving, driven by technological advancements and changing market demands. Several trends and opportunities can be observed:

1. Lightweight and High-Strength Materials: The demand for pitch chains made from lightweight yet durable materials, such as carbon fiber or advanced polymers, is expected to increase. These chains offer improved performance while reducing the overall weight of machinery and equipment.

2. Automation and Industry 4.0: As industries embrace automation and smart manufacturing, pitch chains that are compatible with advanced technologies like IoT (Internet of Things) and robotics will gain prominence. These chains will facilitate seamless integration and contribute to the efficiency of automated processes.

3. Sustainable Manufacturing: With a growing emphasis on sustainability, there is an opportunity for the development of environmentally friendly pitch chains. Manufacturers may explore eco-friendly materials, lubrication systems, and recycling programs to align with sustainable practices.

4. Customization and Specialized Solutions: As industries become more diverse and specialized, the demand for customized pitch chain solutions will rise. Manufacturers that can provide tailored products to meet specific requirements will have a competitive advantage.

Overall, the future of the pitch chain industry holds immense potential for innovation, technological advancements, and expanding applications.

Choosing a Suitable Pitch Chain

Selecting the right pitch chain for your application is crucial to ensure optimal performance and longevity. Consider the following aspects when choosing a suitable pitch chain:

1. Determine Application Requirements: Identify the specific needs of your application, including load capacity, operating conditions, and environmental factors. This will help determine the type and characteristics of the pitch chain required.

2. Identify the Type of Chain: Choose the appropriate type of pitch chain based on the specific demands of your application. Consider factors such as speed, load distribution, and space constraints.

3. Select the Chain Material: Evaluate the compatibility of different chain materials with your application’s operating conditions. Factors like corrosion resistance, temperature tolerance, and lubrication requirements should be considered.

4. Consider the Chain Dimensions: Accurately measure and determine the required chain dimensions, including pitch, roller diameter, and plate thickness. This will ensure proper fit and optimal performance.

5. Check Compatibility with Sprockets: Verify the compatibility of the selected pitch chain with the corresponding sprockets. Proper alignment and engagement between the chain and sprockets are crucial for efficient power transmission.

Conclusion

In conclusion, pitch chain plays a vital role in various industries, offering exceptional performance characteristics such as high strength, low friction, wear resistance, and noise reduction. Understanding the types, characteristics, and applications of pitch chain is essential for selecting the right chain for specific needs. As the industry evolves, future trends indicate a focus on lightweight materials, automation, sustainability, and customization. By considering application requirements, chain type, material selection, dimensions, and compatibility with sprockets, businesses can make informed decisions when choosing a suitable pitch chain. With its diverse applications and continuous advancements, pitch chain remains a critical component in numerous industries.

Author: Dream